Technical insight #1

Philosophy - Acoustics First

1#

Maximise efficiency and linearity using acoustic innovations.

Our primary philosophy is to concentrate on the acoustical design first and foremost. The tools available for correcting problems in a speaker design have evolved radically, thanks to the increases in DSP power. But we strongly believe that concentrating on developing the natural qualities of the loudspeaker design and making them as linear and efficient as possible, before applying DSP techniques, allows our products to exceed expectations.

2#

A system approach; speakers + controller amplifiers + accessories.

An optimised systems approach is the foundation of our philosophy. It enables us to offer simple to use, flexible but powerful systems no matter what the size or application. We take care that each loudspeaker we produce is as acoustically accurate as possible. By ensuring every detail of the design is performing optimally there is a solid foundation from which we can process and power the system. The need for complex DSP is therefore decreased, meaning our approach brings many benefits. Some of these include; increased headroom and dynamics, giving more impact to your mix, improved linearity and reduced need for compensation EQ mean improved coverage across the audience space and these are just a few examples. Our controller amplifiers build on our core acoustic innovations to deliver the energy, accuracy and reliability that brings the best out of our designs.

3#

Focus on what happens in the last 10dB; operation at full power and beyond.

This ties the two previous concepts together and refines them to focus on what is happening at the limits of what a system can deliver. When loudspeakers are reproducing linear sound continually throughout their range, without complex limiting and protection being required, the result is a significant increase in dynamic range. The combination of higher band sensitivity, our ultra efficient class-D controller amplifiers and the expanded dynamic range can easily increase system efficiency by more than ten times.

Last 10dB available?

Sound system is like a sports team; the weakest link defines the overall performance but the peak performer defines the overall marketing.

As sound engineers we all have encountered various sound systems with colourful spec sheets stating max SPL levels that end of the day turn out to be completely something else when used in real life situations. This white paper explains the acoustical approach to minimize these variations through driver loading techniques developed by Aura Audio.

To do this we divide the audio band in hi's and low's from about 300Hz mainly concentrating on most commonly used acoustical solutions such as large compression drivers in mid range and reflex-tuned subwoofers and comparing them to technologies found in A-series and XD-series.

The Hi's

Human hearing is most sensitive in range of 1kHz - 4kHz and although reasons for this is beyond this white paper we can agree that our own vocal range and speech intelligibility plays a big role in human evolution here. This also means that nonlinearities such as harmonic distortion and decay variations are easier to spot by anyone at this frequency range.

It was decided early in A-series designing process that harmonic distortion levels over 3% are not acceptable between 400Hz to 4kHz. This might seem not to be a common problem but apart from a few reviews there are no industry standard for (max)SPL vs. Frequency vs. THD (total harmonic distortion) which could state a linear sound reproduction of speaker system.

Then there's the common argument regarding a musical tone of second harmonic distortion. Although used in music production (tubes started it a century ago) for lots of reasons it's no excuse for poor speaker performance. In fact it's easy to understand that when you have a sound with added second harmonics like an electric guitar for example adding another second harmonic actually turns the original second harmonic into fourth harmonic and so on. This is why we feel that all the harmonics not just third and above should be kept as low as possible and below 3% in any level.

M6 mid range driver used in A-series was developed to answer this issue. Horn-loading was obvious choice as it improves the efficiency and the air lock in horns compression chamber acts as a low pass filter canceling the harmonics. To increase this effect from common 12dB/oct to >18dB/oct an internationally patented multi-path waveguide was developed. This technology also has two additional features: waveform shaping for planar wave front creation and wider bandwidth. Planar wave front contributes to array ability when used in large columns for long through applications.

Wider bandwidth is achieved by low compression ratio for lower high pass frequency and small path length deviations in sound channels contribute to higher cut of frequency in upper frequency range. Higher cut off and crossover frequency of 4kHz enables the use of light moving mass small size compression drivers at highest frequencies with less critical THD performance as these harmonics are for most parts out of human hearing range (for example 3rd harmonic for 6kHz is 18kHz).

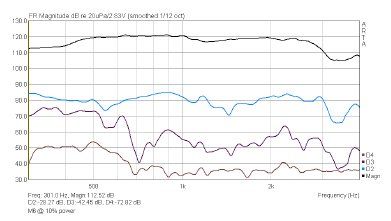

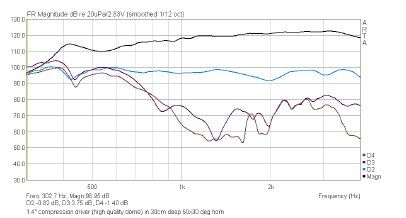

Harmonic distortion measurement with M6 @ 10% Power (120dB continuous SPL). Second harmonic average 1%, 3rd below 0,1% >650Hz and 4th harmonic is almost invisible.

Harmonic distortion measurement with compression driver with high quality dome @ 120dB continuous SPL. Second harmonic average 8% and 3rd and 4th close to 1%. THD average 10%. This solution is somewhat an industry standard way making 2 way and 3 way speakers with xover frequency between 800-2000Hz, in some rare cases even lower than that.

The Low´s

Excursion control

The modern cone driver development has led to a situation where the power handling capability of a driver is less an issue from system development point of view than the maximum linear movement of the cone, excursion. Increasing the excursion means more movement in magnetic field so the motor system size has to increase as well and this leads to a well known treadmill effect. A common solution is so called high loading; band-pass or horn-loading. Both option offer superior advantages to reflex-tuned loading in better sensitivity and lower distortion but are usually larger in size, especially low frequency horns.

XD-series

(eXtended Dual side loading) combines band-pass loading with horn-loading in a scalable enclosure type. The key features in this US-patented technology are very precise impulse response, relatively compact size with high sensitivity and extended cone control beyond lower cut off frequency. The essential innovation is replacing the back volume in band-pass enclosure (either sealed or tuned in common solutions) with a horn. This results in horn-like impulse response without resonator type of long decay at tuning frequency. Lower cut off is mainly result of the horn length and the front chamber acts as a band-pass filter reducing distortion and increasing the overall sensitivity in band-pass region.

Sensitivity and frequency response measurement of standard reflex-tuned subwoofer and XD-subwoofer. Both enclosures are 200 litres size and driven by same 15” long excursion driver. Average sensitivity is increased by 4dB in XD-enclosure.

Average sensitivity differences are compensated to show clearly the decreased cone movement in XD-enclosure. The difference corresponds to 3.5dB average SPL advantage to XD and even more at cut off frequency range, around 40Hz and below in this case.

So even though the difference in sensitivity is minimal at cut off region in both enclosure types the cone control advantage in XD raises the difference back to 4dBs. In many enclosure sizes and driver sizes the difference is closer to 6dB which is a lot!